CONTACT US X

WEBSITE GROUP SITE

Continuous Mix Asphalt Plant

Model:MR80, MR120, MR160, MR200

Production Capacity:

MR Hot Mix Asphalt Plant is continuous asphalt mixing plant. It's designed for portability, durability and reliability. MR hot mix asphalt plant is a cost-effective product which has characteristics of modular design, compact structure and fast set u

Description

High Precision In Aggregates Dosing

When collecting ingredients, the aggregates of different particle sizes that need to be mixed are respectively loaded into different batching hoppers by using a loader, and belt conveyors are arranged under each batching hopper, and the belt conveyor is driven by a frequency conversion speed regulating motor. The ingredients are mixed according to the mixing ratio of the construction technology; the matched materials are dropped on the horizontal aggregate belt conveyor, which is transported through the filter screen to the inclined belt conveyor.

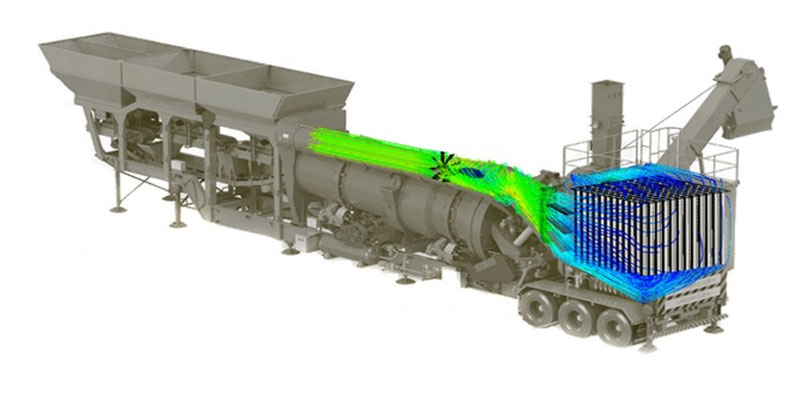

Counter-flow Dryer

The drum counter-flow rotary drying heating method is provided with a spiral rewinding blade and a feeding blade in the cylinder body, and different shapes of reversing blades are installed in different regions, and the drum cylinder body has an inclination angle of about 3.5-4 degrees, and the outer layer has 40cm of thermal insulation rock wool prevents heat loss.

- Fully dedicated to aggregates drying and heating. It operates in a counterflow system, in which the heat is applied gradually over the aggregates, respecting the physical laws for moisture extraction, ensuring high productivity and low fuel consumption.

- Designed using advanced computerized simulation systems, it has fins designed to efficiently meet all the steps of the drying and heating stage with maximum efficiency, ensuring complete elimination of moisture, correct temperature and high throughput

- Automatic control of the dryer spin speed results in the maximum heat exchange between the aggregates and fuel gases

- Intelligent exhaust system that ensures perfect combustion regardless of the production rate

Air Burner

The fuel burner is controlled by a single-chip microcomputer program. Simply press the “Start” button to start the oil pump, auto-ignition, flameout alarm, automatic temperature control and display. The fuel can be automatically adjusted according to the required furnace temperature. . It is also equipped with a manual function to ensure the normal operation of the burner through a manual system when the system fails.

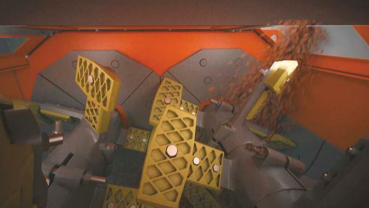

Twin-shaft Reverse Pugmill Mixer

The mixing machine adopts the horizontal double-shaft paddle type spiral stirring method, the stirring blade, the stirring arm and the lining plate are all made of chrome-molybdenum alloy wear-resistant cast iron, and the stirring arm is made of cast steel material. It has strong corrosion resistance and wear resistance, which greatly prolongs its service life.

Baghouse

High dust removal efficiency, dust removal up to 99%; flexible use, processing air volume from hundreds of cubic meters per hour to hundreds of thousands of cubic meters per hour, can be used as a small unit directly in the room, near the machine tool, can also be made into a large dust removal The room, that is, the bag room; the mechanism is simple, the operation is stable, and the maintenance is convenient.

Control Room

All plant controls are mounted on a centralized panel inside the control house. All of the plant's motors and switches are pre-wired and factory tested. Quick-plug connectors aid in rapid plant setip. The air conditioned control house is trailer-mounted for easy portability. It also includes heating, lights, internal power outlets and a sliding ticket window.

Technical Parameters

|

Configuration |

MR100 |

MR160 |

MR200 |

|

|

Production capacity |

100 t/h |

150 t/h |

200 t/h |

|

|

TRANSPORT |

||||

|

Mobilities |

1 |

2 |

||

|

Axles/Tires mobility 1 |

3 / 12 (+ 1 spare) |

2 / 8 (+ 1 spare) |

||

|

Axles/Tires mobility 2 |

3 / 12 (+ 1 spare) |

|||

|

Suspension / Brakes - mobility 1 |

Triple tandem / ABS |

Double tandem / ABS |

||

|

Suspension / Brakes - mobility 2 |

Triple tandem / ABS |

|||

|

Size(L*W*H) |

21.30 x 3.20 x 4.30m |

21.30 x 3.20 x 4.30m |

13.90 x 3.20 x 4.30 / 17.10 x 3.20 x 4.30m |

13.90 x 3.20 x 4.30 / 19.00 x 3.20 x 4.30m |

|

DOSING SYSTEM |

||||

|

Number of Bins |

4 |

|||

|

Bin volume |

2 of 10m³ + 2 of 5 m³ |

10 m³ |

||

|

Aggregate weighing |

Individual dynamic weighing by centralized high precision compression load cells, with an individual capacity of 200kg |

|||

|

Speed sensor |

Inductive sensor for speed check (pick up) |

|||

|

Wall Vibrator |

3 standard vibrators in bin 1. Optional vibrators in bin 2 |

|||

|

DRYING SYSTEM |

||||

|

Technology |

Counterflow dedicated exclusively to the drying and heating of aggregates |

|||

|

Burner |

SINOROADER Total Air® |

|||

|

FILTERING SYSTEM |

||||

|

Technology |

Twin-shaft reverse pug mill with arms and straws |

|||

|

Mixing steps |

Dry mixing and mixing with asphalt cement |

|||

|

Mixing time |

Configurable |

|||

|

Cleaning |

With lower deck |

|||

|

Wear elements |

High abrasion resistance material |

|||

|

Asphalt Injection |

With sprinkling nozzles |

|||

|

TRANSPORT AND STORAGE SYSTEM |

||||

|

Mix Transport Technology |

Redler type drag lift |

|||

|

Wear elements |

High abrasion resistance material |

|||

|

Bin volume |

1 m³ |

2 m³ |

||

|

Type |

Maximum level sensor, anti-saturation window, anti-segregation plate, inspection flap |

|||

|

CONTROL SYSTEM |

||||

|

Operation cabin |

Metallic with side door, containing control panel, supervisory, buttons for actuation in manual and PLC |

|||

|

Sistema de climatização |

7,000 BTU air conditioning with inverter technology |

|||

|

Critical Control |

Automatic (supervisory) or emergency mode (by supervisor + manual operation buttons) |

|||

|

SAFETY |

||||

|

OPERATION |

PRODUCTION |

|||

|

Feed bins |

Fixed protections for mobile parts |

– |

||

|

Emergency button |

||||

|

Dryer |

– |

Reading of the rotational speed with interlocking |

||

|

Dryer / burner |

Emergency button |

Flame sensor - UV photocell |

||

|

Pick up dryer monitoring |

||||

|

Mixer |

Emergency button |

– |

||

|

Bag Filter |

Emergency button |

Temperature sensor |

||

|

Cold Air Damper |

||||

|

Emergency valve |

||||

|

Control cabin |

Emergency button + internal audible alarm |

– |

||

|

Operating interface in extra low voltage (24V) |

||||

|

Power Panel |

Security PLC Monitoring |

– |

||

|

Command circuits with 2 counters connected in series |

||||

Address : No. 1001 Longxiang Industrial Park, Weidu District,XuChang,HeNan, China

Tel : 4000-676-878

Code : 461000

Email : sales@sinoroader.com

Wechat : Sinoroader

Address : No. 99 Beston Machinery Park, Erqi District, ZhengZhou, HeNan, China

Tel : 4000-676-878

WhatsApp :+86 18224529750

Email : sales@sinoroader.com

RU

RU MM

MM AR

AR

Wechat:+86 18224529750

Wechat:+86 18224529750