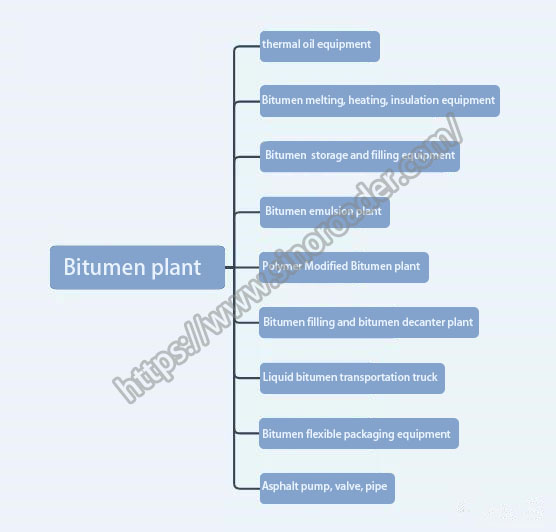

Road construction and maintenance machinery classification : bitumen processing equipment

Bitumen is the most important road building binder in the world, and the machinery and equipment for bitumen processing is an important part of road building and maintenance machinery.The main equipment includes bitumen storage and transportation equipment, heating and melting equipment, character improvement and processing equipment.

Bitumen heating treatment equipment classification

1. Thermal oil equipment

Bitumen viscosity changes with temperature, only after heating can be processed and used.The heating mode includes direct heating and indirect heating. At present, direct heating is mainly in the form of heat pipe, indirect heating is mainly in the form of heat conducting oil, and direct flame heating is basically unused.

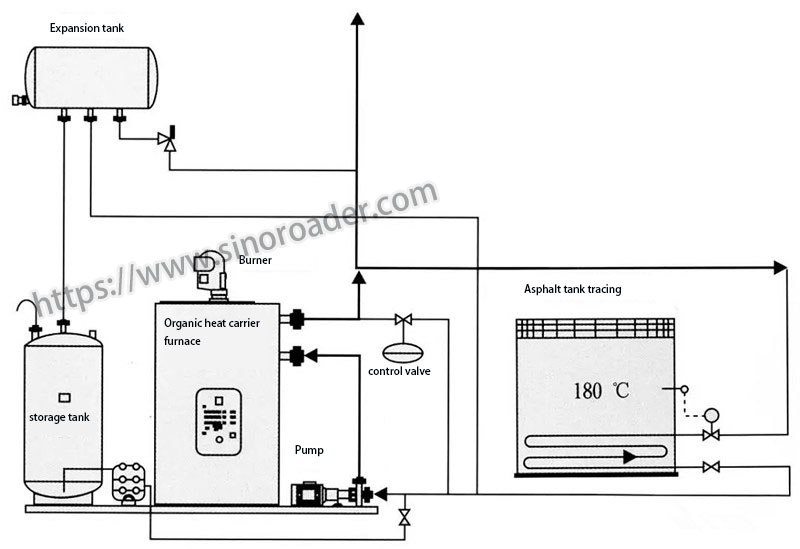

Thermal oil equipment, is a common way of heating .Thermal oil absorbs the heat of fuel combustion, and then heat bitumen with hot oil, which can keep bitumen from burning and aging.

The structure of thermal oil equipment is generally divided into vertical type, horizontal type and truck type, and the thermal power is generally 10-20 million kcal (12-24000kw).In addition, electric heating, water heating, steam heating and other ways.

Thermal oil equipment

Thermal oil equipment is generally composed of furnace body, burner, storage tank, expansion tank, hot oil pump, pipeline, control valve, electric control device and other parts.

Heating schematic

2. Bitumen storage (station)

Bitumen storage (station) is the place where bulk bitumen is stored and transferred. It is usually built in seaports, docks and railway stations to receive liquid bitumen from unloaded ships and trains.The bitumen storage is mainly equipped with conveying pipeline, thermal oil equipment, receiving and unloading device, filling device, laboratory, modification and emulsification workshop.

Bitumen storage model

3. Bitumen storage tank

Each storage tank storage capacity is generally 500 ~ 2000t, internal heating pipe, external wrapping rock wool insulation materials.

Bitumen storage tank

4. Liquid bitumen transportation truck

Liquid bitumen transportation truck is suitable for medium and short distance transportation, keep the bitumen in hot liquid state, the truck is equipped with heat preservation and heating equipment and anti-surge baffles.

Liquid bitumen transportation truck

5. Bitumen heating tank

Bitumen heating tank is mainly heating, and output hot bitumen as required temperature.

Bitumen heating tank

6.Polymer Modified Bitumen plant

Polymer Modified Bitumen plant is to add rubber, resin and other polymers to bitumen to form a stable mixture.It can improve the adhesion and high and low temperature resistance of bitumen.

Polymer Modified Bitumen plant

Polymer Modified Bitumen plant consists of bitumen storage tank, heating tank, colloid mill, finished tank, pump, valve and control system.

Polymer Modified Bitumen plant

7.Bitumen emulsion plant

Bitumen emulsion plant is an equipment that mixes water and bitumen together to form emulsion under the action of emulsifier.Emulsified bitumen can be used at room temperature.

Bitumen emulsion plant

Colloid mill is the key equipment for producing modified bitumen and It mainly plays the role of breaking and dispersing.

Colloid mill

8. Bitumen pump and valve

Bitumen pump, valve is bitumen processing equipment center indispensable parts, a lot of kinds, commonly used bitumen pump: involute gear pump, internal gear pump, three screw pump, double arc gear pump.

Gear bitumen pump and manual valve

Bitumen pump and pneumatic valve

9. Bitumen filling and bitumen decanter plant

Bitumen filling and bitumen decanter plant is an important equipment for bitumen transportation,Soft packing bags are made of special materials that can be melted with bitumen.

Bitumen soft packing drop line

Barrels of bitumen is a common form of transport packaging, the use of special equipment to take out the bitumen, bitumen decanter plant.

Bitumen decanter plant.

RU

RU MM

MM AR

AR