Concrete Batching Plant Introduction

Definition

Concrete batching plant, known as concrete plant or concrete batch plant, is a combined device used to mix and form concrete. Its high mechanization and automation improves the productivity, guarantee the concrete quality and save cement consumption. It is widely used in large/medium hydropower, power plant and bridge constructions.

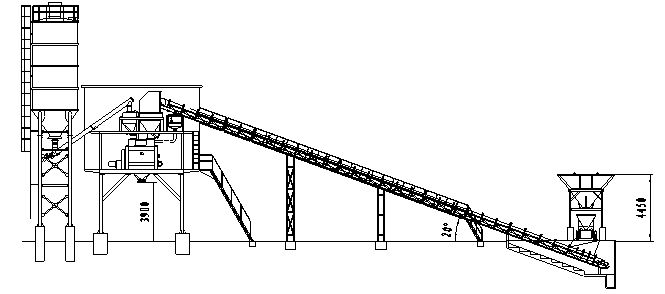

Structure

The concrete plant mainly consists of aggregate batching system, mixing system, cement supply system, water supply system, electricity and control system.

The mainly consists of aggregate bin, weighing hopper, and belt conveyor; the mixing system mainly consists of twin-shaft concrete mixer, reducer, cement weighing hopper, water and additive weighing hopper; the cement supply system is consisting of cement silo, screw conveyor, air compressor, and screw scale; water supply system is consisting of water tank, pump and pipeline; electricity system consists of computer control panel, electricity cabinet, and control room; control system can be PLC or manual operate.

Working principle

First, turn the electricity on so that the system starts to initialize the batching, grading, concrete slump, and productivity.

Second, inspect the batching system and weighing hopper according to the recipe, use the empty/full signal of aggregate bin to determine if start the mixing program and feeding system.

Third, open the butterfly valve for flyash and cement tank, then start the screw conveyor to deliver the flyash and cement to weighing hopper; open the control valve at the water tank and additive pool to allow the water and additive to flow into the weighing hopper; open the hopper gate if the mixture meets the requirement to let the mixture enter the twin-shaft mixer for mixing.

Forth, open the mixer gate to discharge the concrete into the transit concrete mixer truck when the mixing time runs out.

Safety regulation

1. The silo is not allowed to be tilt, the support outrigger be deformed during the installation process;

2. The outrigger bottom should be firmly welded onto the pre- foundation.

3. Take measure to prevent wind and lightings.

4. Avoid strong impact the outriggers and silo body.

5. Regularly inspect the bag filter in the collector and remove cement timely.

6. Foundation should be firm enough and in compliance with the construction design regulation.

7. Pressure in the silo will be higher than the rated one for safety valve is the bag filter is blocked. Open the valve in this case to release the pressure in order to prevent explosion.

8. The cement silo should be vertically put onto the precast concrete foundation in advance by the crane.

RU

RU MM

MM AR

AR