Trailer Pump Introduction

The trailer pump, short for trailer type concrete pump, is a device of concrete machinery used to convey and grout the concrete in the construction. Our trailer pump can continuously work for 12h and medium can be silt, slag, waste materials or mortar. It features high output and high pressure, so it is widely used in high-rise buildings, high-distance pumping, tunnel construction, sludge pumping and others.

Working principle

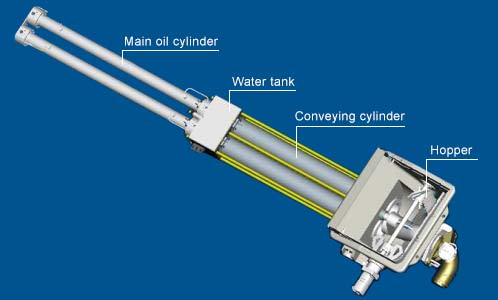

When the pressure oil enter one main cylinder, the piston in the other cylinder will force the main cylinder to retract with help of hydraulic oil due to sealing; conveying piston connected to the piston rod will retract at the same time to generate negative pressure, the main oil pressure will work onto the piston rod to push the concrete piston work, the concrete will be delivered into the pipe through sliding valve. When the movement is complete, the control valve will automatically change the direction with the PLC and control oil so that the pressure oil enter the other main cylinder to fulfill another suction and conveying process.

Classification

The trailer pump can be divided by concrete delivery pressure into low pressure trailer pump (≤5MPa), medium pressure trailer pump (6-10MPa) and high pressure trailer pump (>5MPa). It can be also divided by delivery volume into different types ranging from 20m3 to 100m3, and most can realize two-step or stepless variable displacement.

How to choose

The user can select a right trailer pump based on actual need: theoretical delivery pressure is determined by delivery height; theoretical delivery volume determined by mixing capacity; distribution valve determined by aggregate. Butterfly valve is suitable for all aggregates, but the swinging cross section for direction changes is larger, so good for low and medium pressure trailer pump for infrastructure construction; for S-vavle, the pressure loss is less, pipe is smooth, but it is restricted by the pipe diameter and picky about the aggregate, suitable for medium and high pressure trailer pump for high buildings or long distance / high head delivery of high quality concrete; gate valve performance is between butterfly valve and S-valve, widely used for medium pressure pump.

Model

Take HBTS60-13-90 trailer pump for example to present the model meaning in China.

HB: presents concrete pump;

T: trailer type;

S: S-valve (D for butterfly valve, Z for gate valve);

60: max theoretical delivery volume, unit is m3/h;

13: max delivery pressure, unit is MPa;

90: motor power, unit is kW.

Preparation work

1. Make sure the trailer pump should be installed onto flat firm surface, four legs onto the ground so that the tyres bear no load. If the surface is soft, place wood plates to prevent sinking.

2. Inspect the pipe layout and joints to ensure the straight pipes are in the same line, stringing pipes are constructed correctly, and joints are sealed properly.

3. Make sure the water tank and hopper are full of water.

4. Inspect the oil level in the hydraulic oil tank and pump oil tank, add where necessary. For manual pump oil, check the lubrication performance at each point.

5. Inspect the cable joint condition and make sure the witches are at off position. Then turn on the power to start the motor and monitor its rotation so that the motor can work normally.

6. Before starting the motor, inspect the hopper screen and gate, remove foreign materials from the hopper.

7. Let the machine rotate for a while without any load if it is rather cold in the winter, then feed when the hydraulic oil temperature reaches 20C.

8. After rotating 10 minutes, inspect if the pressure meter works normally, mixing device rotates counterclockwisely, positive/negative pump works well.

RU

RU MM

MM AR

AR