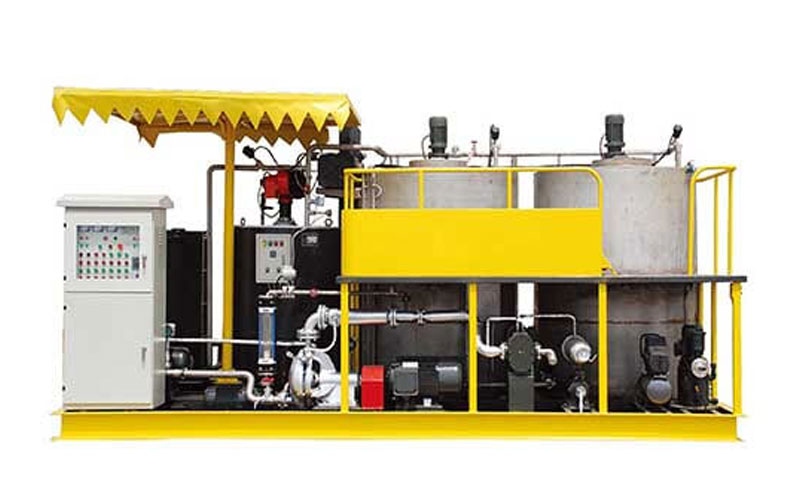

How to Guarantee Emulsified Bitumen Equipment Production Quality?

An important index for measuring the quality of emulsified bitumen produced by emulsified bitumen equipment is the degree of fineness of the asphalt particles. Therefore, the higher the degree of refinement of the product, the better the performance and storage stability of the emulsified bitumen. The process of crushing and dispersing bitumen liquid phase using emulsified bitumen equipment is a very complicated mechanical process. Generally, the crushing and dispersion of bitumen liquid phase is completed by using shear, extrusion, friction, impact and expansion and diffusion. And we also need to know more about emulsified bitumen equipment.

The degree of refinement of the materials produced by the emulsified bitumen equipment has a very direct relationship with the emulsifier in the emulsified bitumen equipment used to produce the emulsified bitumen, which is the heart of the emulsified bitumen equipment. Therefore, the performance of the emulsifier has an important impact on the quality and stability of the emulsion. At present, emulsified bitumen equipment is mainly divided into three categories, so the degree of refinement of emulsified bitumen production directly affects the best-selling problem of emulsified bitumen equipment. Therefore, when we purchase emulsified bitumen equipment, we should choose an emulsifier with a high degree of uniformity, so as to ensure the production quality and stability of the emulsified bitumen.

See the different processes of emulsified bitumen equipment

Emulsified bitumen equipment is classified according to the process flow, which can be divided into three types: intermittent operation, semi-continuous operation and continuous operation.

1. Batch modified emulsified bitumen production equipment. During production, emulsifiers, acids, water, and latex modifiers are mixed in a soap liquid mixing tank, and then pumped to the colloid mill in the bitumen. After one can of soap is used up, configure the soap, and then proceed to the production of the next can. When used in the production of modified emulsified bitumen, depending on the modification process, the latex pipeline can be connected either before or after the colloid mill, or there is no dedicated latex pipeline. Instead, the specified amount of latex is manually miserable Add to soap tank.

2. Semi-continuous emulsified bitumen production equipment, in fact, batch-type emulsified bitumen equipment is mostly equipped with soap liquid mixing tanks, so that soap liquid can be mixed alternately to ensure uninterrupted delivery of soap liquid to colloid mill. At present, a considerable number of domestic emulsified asphalt production equipment belong to this type.

3. Continuous emulsified bitumen production equipment, which pumps emulsifier, water, acid, latex modifier, bitumen, etc. directly into the colloid mill with a metering pump. The blending of soap liquid is done in the conveying pipeline.

RU

RU MM

MM AR

AR