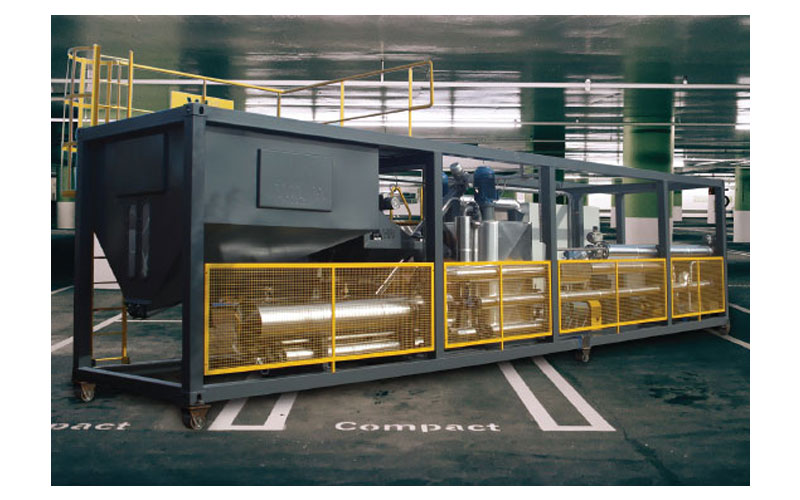

Characteristics of Polymer Modified Bitumen Plant

The Polymer Modified Bitumen Plant is used for modifying asphalt, which consists of colloid mill, modifier feeding system, finished material tank, asphalt heating mixing tank, computer control system and electronic weighing device. The entire production process is controlled by a computer automated program.

The asphalt modification equipment has the advantages of reliable quality, stable performance, accurate measurement and convenient operation, and is an indispensable new equipment in highway construction.

Main Features:

1. Colloidal grinding, fixed cutter channel guide groove diameter is specially designed to greatly increase the flow rate of rubber powder polymer modified asphalt.

2. Colloid grinding and fixed cutter disc are processed by metal processing heat treatment, high hardness, suitable for cutting rubber particles with high elasticity and improving fineness;

3. Increase the high line speed, up to 50~60/sec;

4. The rubber powder can be added in an amount of 2-7%, which is 1-2 times that of the general rubber powder modified asphalt equipment.

RU

RU MM

MM AR

AR