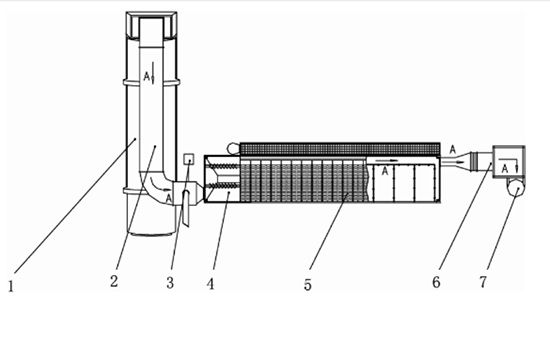

Structure design of dust removal system of asphalt mixing plant

The function of the dust removal system is to collect and process the combustion exhaust gas generated in the drying drum and the dust generated in each other device, and emit the gas that meets the environmental protection requirements. It is composed of first-level flue, first-level gravity dust collector, second-level bag dust collector, second-level flue and induced draft fan. The dust with larger particle size is separated and collected by the gravity dust collector, and the bag dust collector filters the fine dust. In order to facilitate transportation, installation, and compact structure, the first-level gravity dust collector and the second-level bag dust collector are integrated into a whole.

1. Drying drum 2. Flue 3. Temperature sensor 4. Gravity dust collector 5. Bag dust collector

6. Induced draft fan 7. Chimney A. Gas

1. Dynamic dust collector

If the inlet dust concentration is high, the outlet concentration is also high. As the efficiency of dust removal increases, the dust concentration at the outlet will decrease, but the efficiency has its limitations. If it exceeds a fixed value, it is difficult to increase. In order to reduce the outlet dust concentration, the inlet dust concentration should be reduced as much as possible. The actual production volume should not exceed the designed production capacity, this can ensure the dust discharge concentration, and can also extend each row.

The life of gas pipeline and screw feeder.

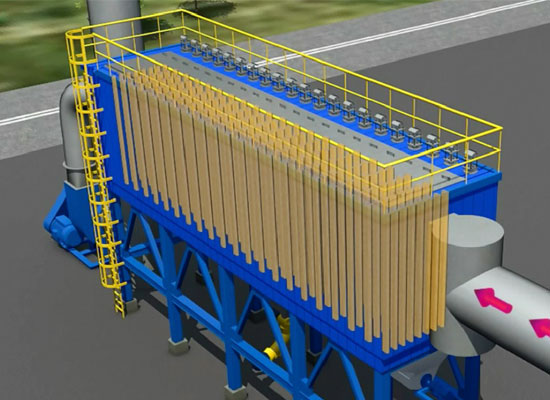

2. Bag dust collector

The bag dust collector uses the principle of atmospheric back blowing to clean the bag, so the dust collector must work in a negative pressure environment. Dust-containing gas enters the entrance of the bag dust collector. After being filtered by the bag, the dust adheres to the bag. The purified air is discharged into the atmosphere through the induced draft fan. Air is periodically blown into the bag dust collector to remove dust adhering to the bag. All cloth bags are divided into several compartments, and each compartment is completely sealed from each other. --Secondary cleaning-one compartment, so the bag dust collector can remove dust and clean at the same time. The collected dust is discharged through the screw feeder and impeller feeder. During the process of using the bag filter, the screw feeder and impeller feeder should always be in working condition to avoid dust accumulation at the bottom.

3. Atmospheric blowback

The bag dust collector can be divided into multiple bag compartments. In the dust-cleaning stage, the dust collector will force air from the inlet to the outlet of the bag due to the existence of negative pressure, so the bag will be swelled, so that the dust deposited on the outer surface falls into the hopper. The screw conveyor at the base of the hopper discharges the dust to the outside.

RU

RU MM

MM AR

AR