How to select dust removal equipment for asphalt mixing plant?

Common dust removal equipment for general asphalt mixture mixing equipment include dry dust collector, wet dust collector and bag dust collector. Dry dust collector is used as primary dust collector, and wet dust collector and bag dust collector are used as secondary dust collector. Different dust removal methods can be adopted according to different requirements.

The dust collector of asphalt mixing plant has simple structure and low cost. It has many structural types such as spray type, which can achieve a certain dust removal effect. However, it has the problem of secondary pollution, because the dusty wastewater will be gradually acidified by sulfur and nitrogen in the flue gas in the process of recycling, the acidified water will corrode the steel, and the arbitrary discharge will form secondary pollution to the surrounding environment. Therefore, the use of wet dust collector in asphalt mixture mixing equipment has been reduced day by day.

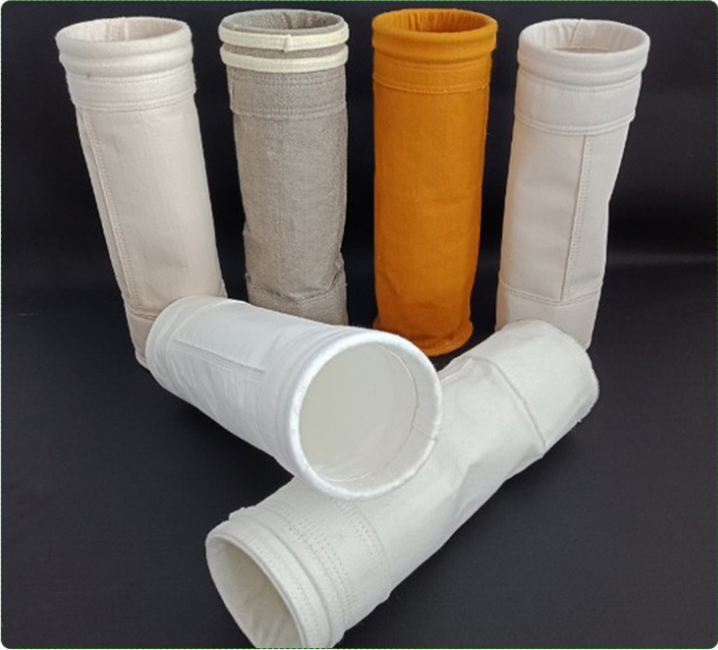

Bag filter has been proved to be an ideal dust removal system for asphalt mixing equipment, which can filter 0.5 μ M above, the dust removal effect is good, and the dust discharge concentration can be less than 50mg / Nm3.

The bag pulse dust collector is selected. The bag adopts high-temperature bag, which has long service life and simple maintenance. It has much better dust removal effect than the original atmospheric reverse blowing dust removal effect, and the water curtain dust removal effect is relatively poor, which will also cause secondary pollution.

RU

RU MM

MM AR

AR